Service Hotline

About August

August • What services can we offer

Plastic Product Design - Product Development - Precision Mould Manufacturing - Processing and Moulding - 24 Hours after sales service

Product 2D Design

Product 2D Design

3D Design

3D Design

Electronic Scheme Design

Electronic Scheme Design

Proofing

Proofing

mold development

mold development

Mass production delivery

Mass production delivery

After-sales service

After-sales service

Product 2D Design

According to customer needs, we can provide market research and competition analysis, with the original design as the core, and we can also offer 3D drawings or samples according to customer requirements, optimize the structure of injection moulded parts, and achieve an efficient combination of design and structure.

Service Hotline

3D Design

Configure 3D machinery and equipment to provide rapid prototyping services for the development of new products designed by customers, realize a high degree of integration of design and manufacturing, promote the efficiency of new product innovation, shorten the development cycle of new products, and improve product quality and competitiveness.

Service Hotline

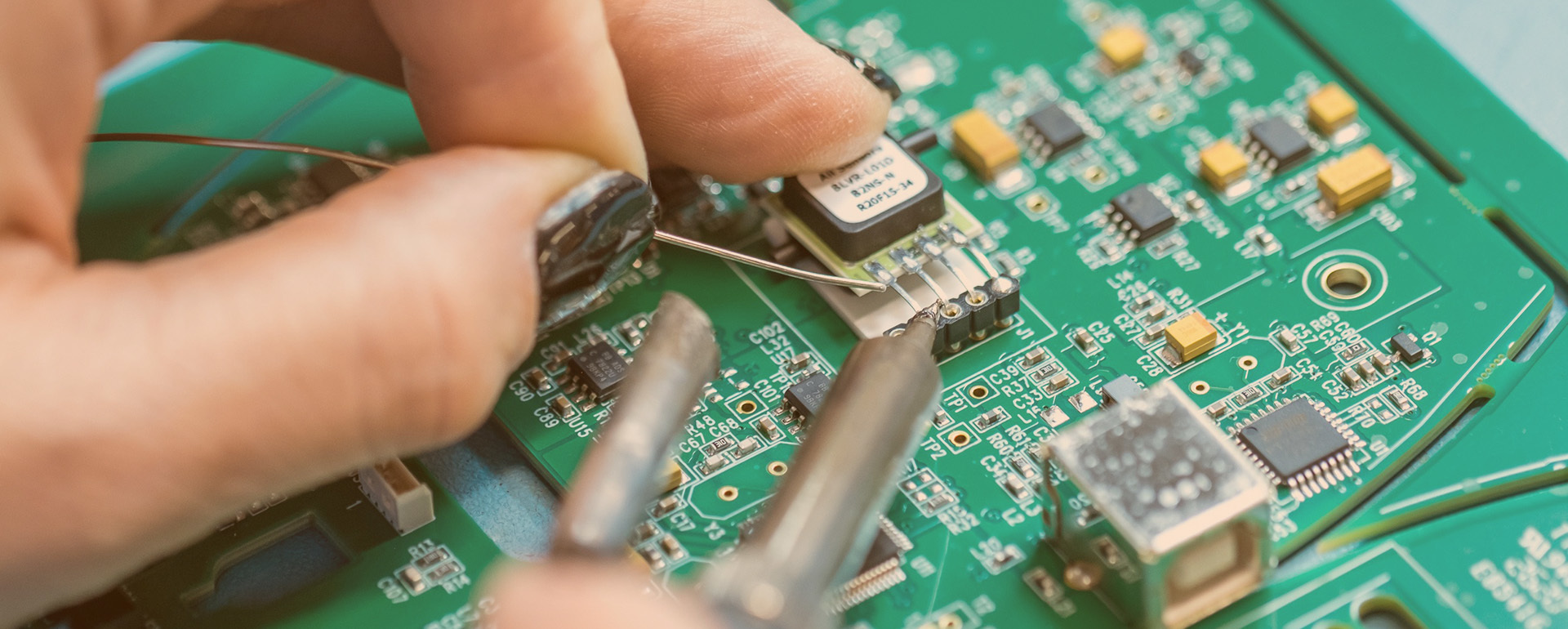

Electronic Scheme Design

Based on the professional design concept, we are constantly innovating, from the appearance design of the product to the improvement of electronic functions, the combination of structure and electronics, and finally realize the landing of customer solutions, ensuring the safety of products while complying with the national mandatory CCC standard.

Service Hotline

Proofing

Through the rapid verification technology of 3D printing, the early development time and development cost of the product can be shortened, and the fine features can reach 0.02mm, thus avoiding the risk of the product not meeting the market demand after mould opening and injection moulding.

Service Hotline

mould development

We can meet the development and design requirements of different products. According to the product structure and product characteristics, through superb cutting, precision mirror discharge, and high-precision wire-cutting processing technology, combined with three-dimensional testing equipment, it can finally maintain precision and smoothness without geometric deformation.

Service Hotline

Mass production delivery

With a complete production management team and advanced equipment, it can complete injection moulding, pad printing, spray coating, finished product assembly and mass production and shipment in the factory. We have successfully assisted 5,000 customers to achieve mass production and achieved good results.

Service Hotline

After-sales service

Each project has a dedicated person to carry out docking follow-up and provide 24-hour online service. For the problems reported by customers, we will reply and solve the problems within 2 hours. If there is any quality problem, we provide a refundable after-sales service.

Service Hotline

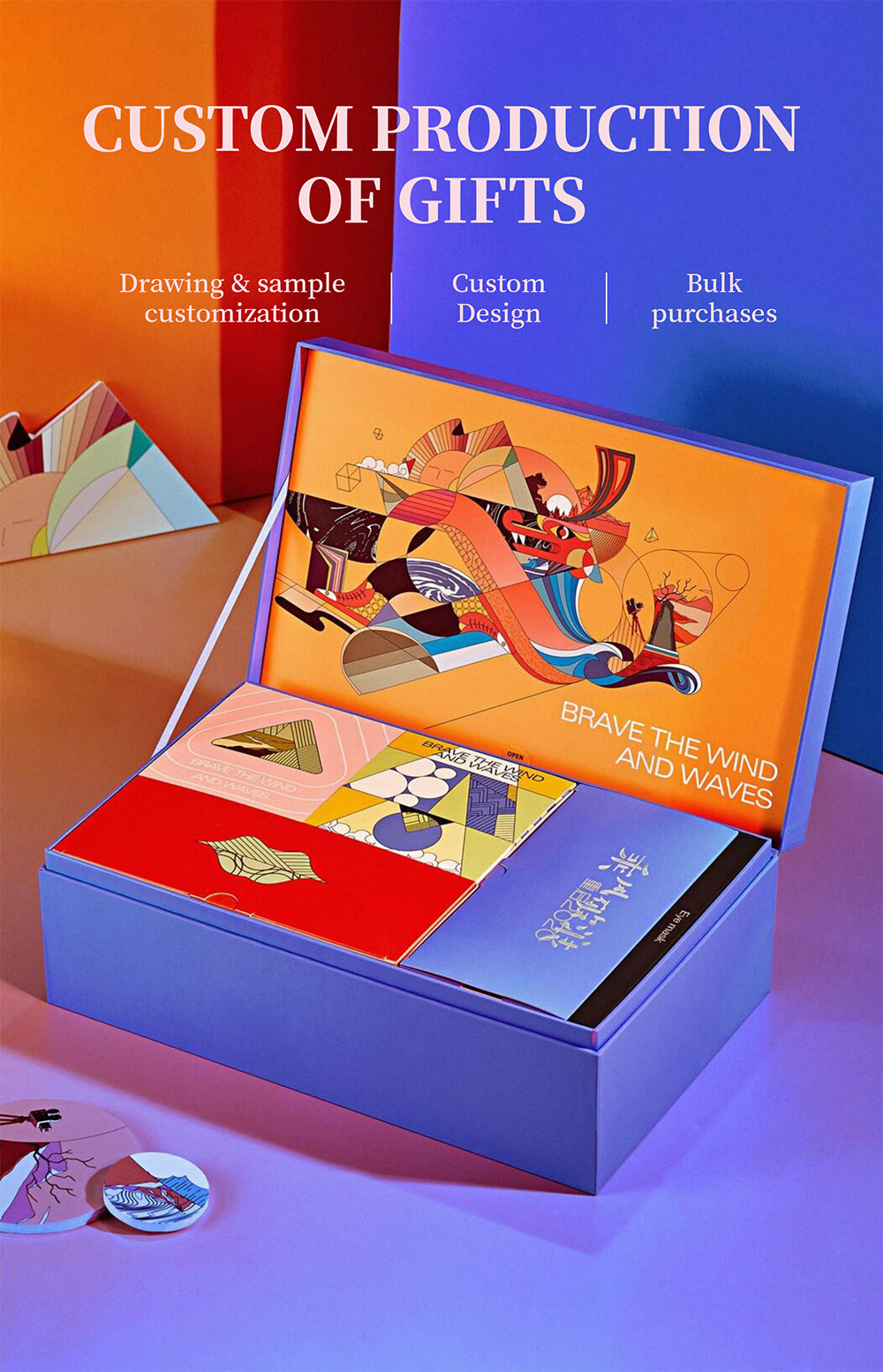

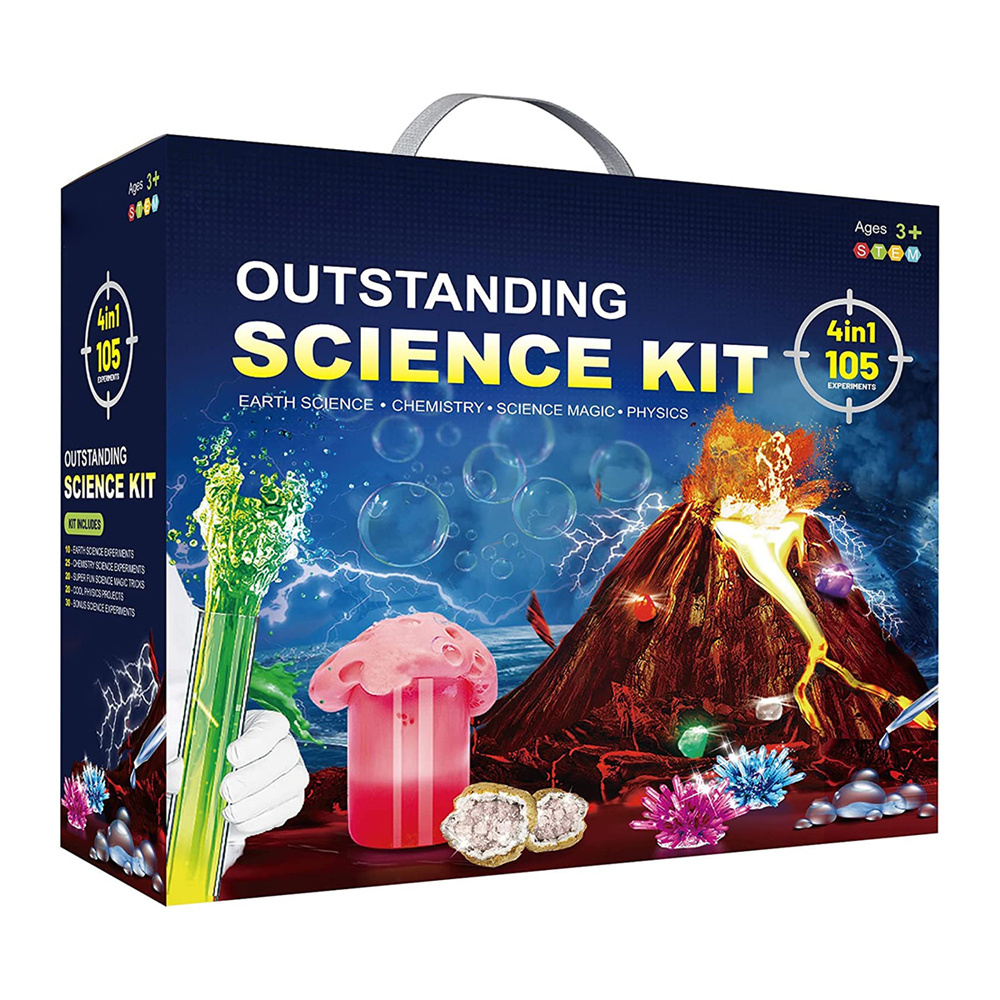

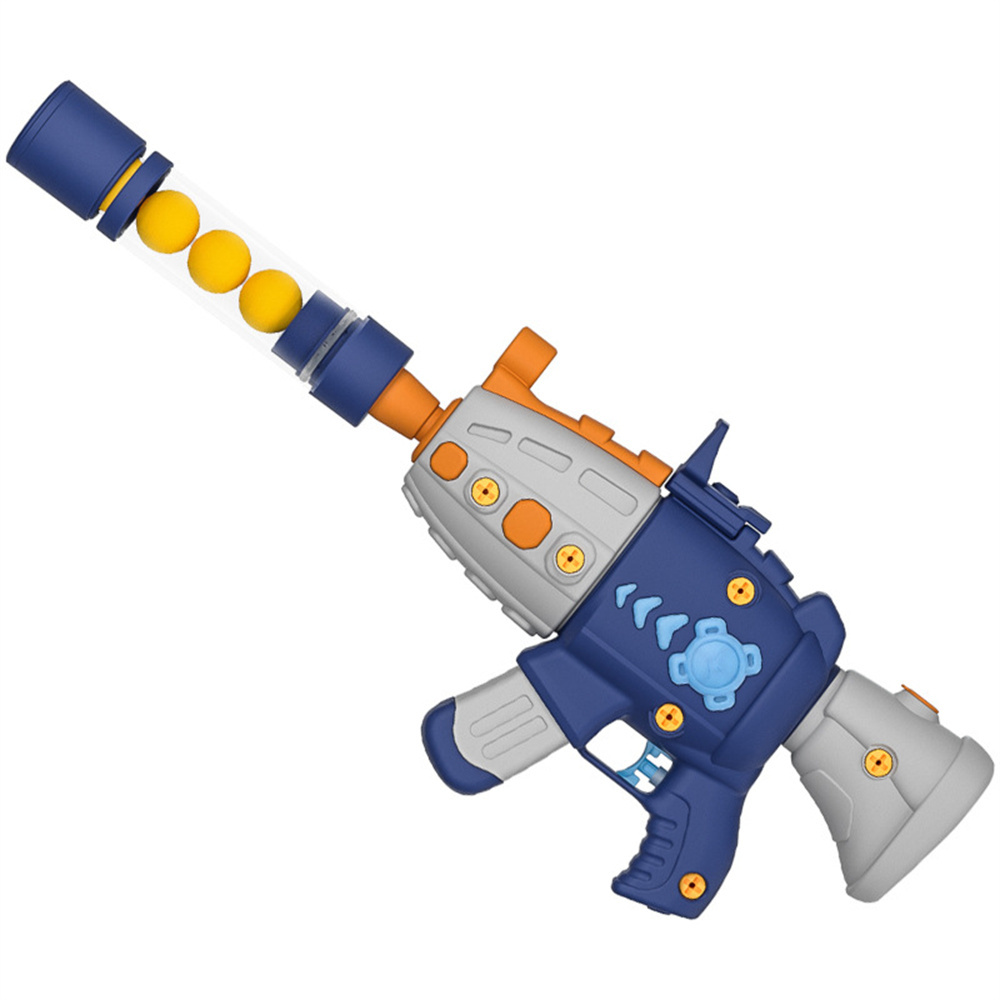

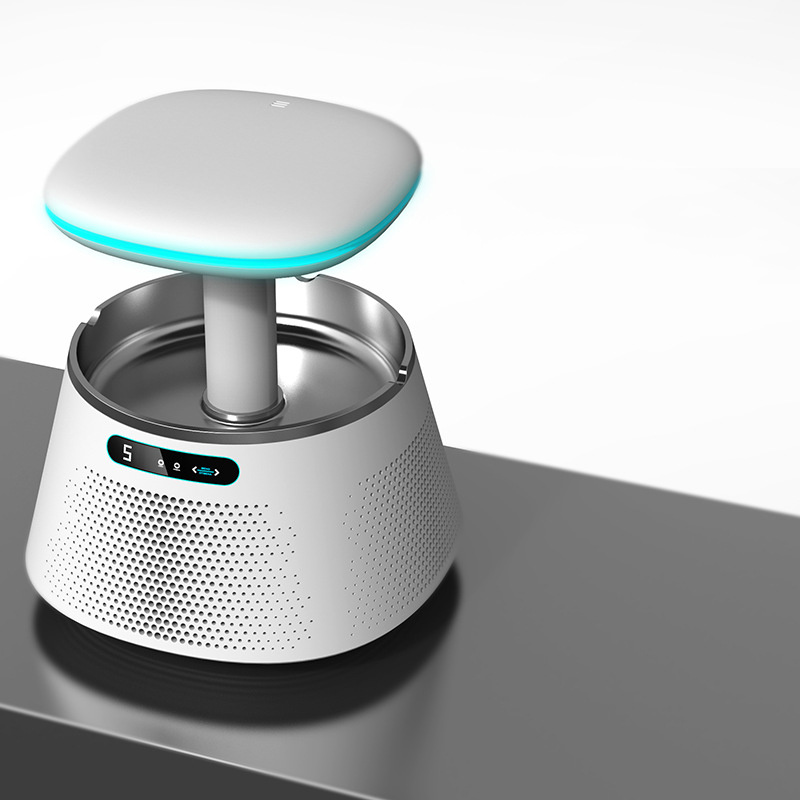

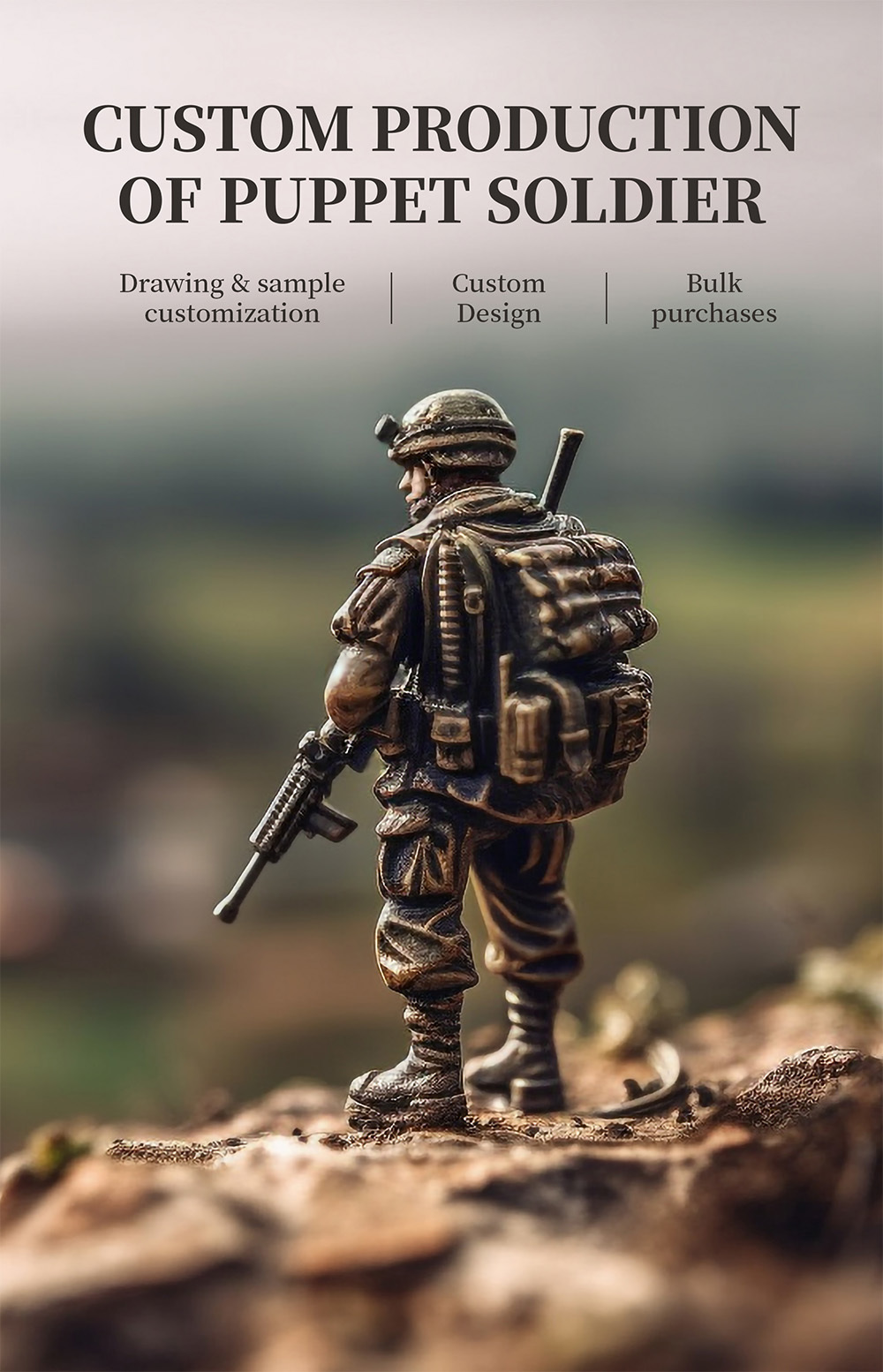

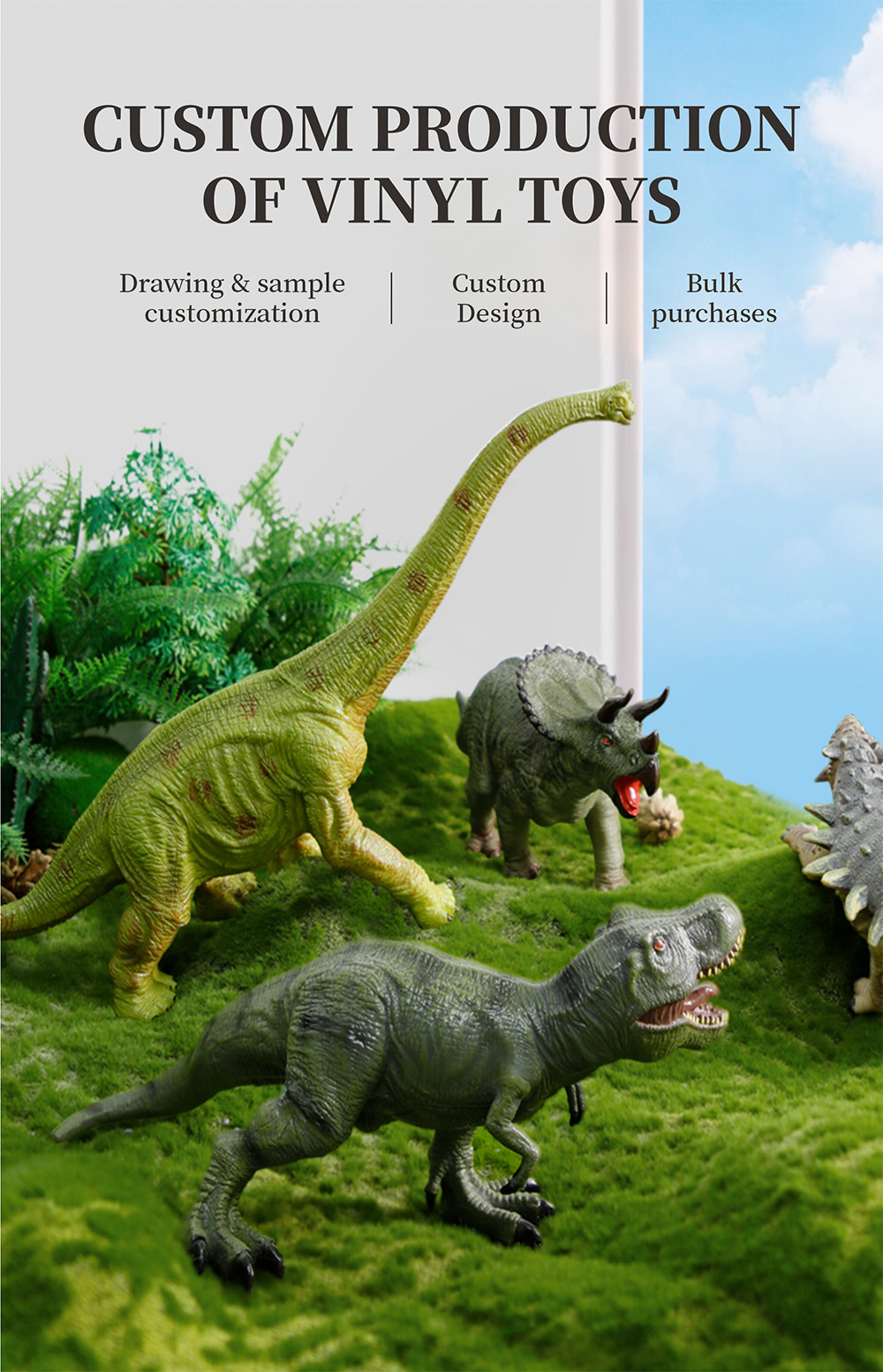

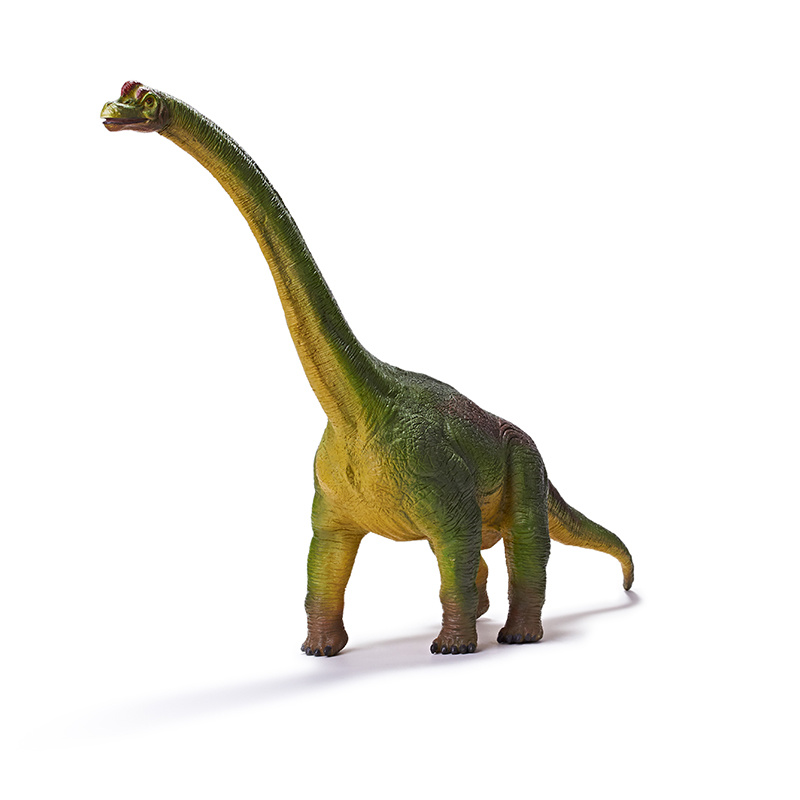

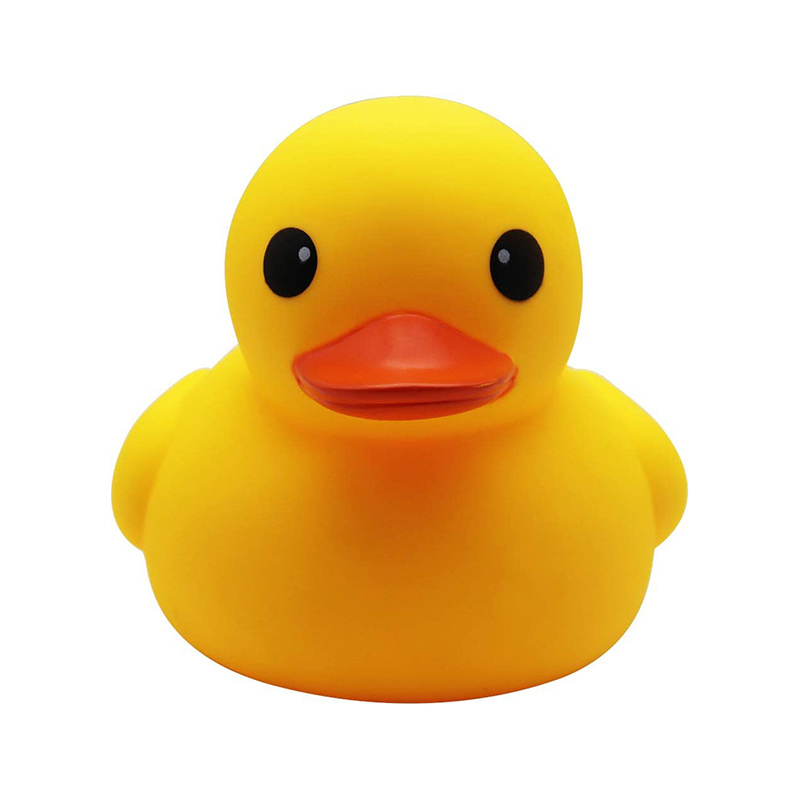

August • Sample Showcase

National standard, American standard, German standard and European standard are complete, and can be customized on demand

August Plastic

High-end brand plastic toys, plush toys, customization services provider

Huizhou August Plastic Product Co., Ltd. (abbreviation as "August Plastic") was established in 2018 and is headquartered in the city with the most robust manufacturing industry in China — Huizhou.

August Plastic has a large-scale production base of 10,000 square meters, 150+ skilled production teams, and 20 exclusive development and design teams. Our factory has a production planning department, production engineering department, quality department, injection moulding department, adhesive department, assembly department, spraying department, packaging department and warehouse department.

We have introduced many imported production equipment, adopting the combination of automatic production line and manual production, with a daily production capacity of more than 10,000 pieces. It has a mature supply chain system, implements digital management, and intelligent production, and ensures timely delivery according to quality and quantity.

World Quality System Certification

Team of Skilled Craftsmen

Excellent reputation for customer projects

Processing and manufacturing base

August • Business Partner

August • Manufacturing Strength

Ensure continuous and stable injection moulding production • Accelerate mass production and delivery of products

10000+ ㎡ Manufacturing Base

professional

The production base exceeds 10000 ㎡, with a daily production of 10000, a global cooperative customer 100, and is favored by major brands at home and abroad.

150+ Team of Skilled Craftsmen

Technical

Fine division of labor, specialized operations, efficient production, the company's internal division of labor is clear, including engineering department, mold department, injection molding department, vinyl department, assembly department, spraying department, packaging department, etc.

30 days to complete the delivery period

Efficiency

Equipped with a variety of imported advanced production equipment to meet different production needs, and a team of engineers and craftsmen who are proficient in technology, through scientific and refined production management, to achieve high-quality and efficient production to ensure timely delivery.

August • Quality Control Strength

Master the core technology, and strictly control the processes at all levels

11 quality inspections are strictly controlled, with a pass rate of 99%

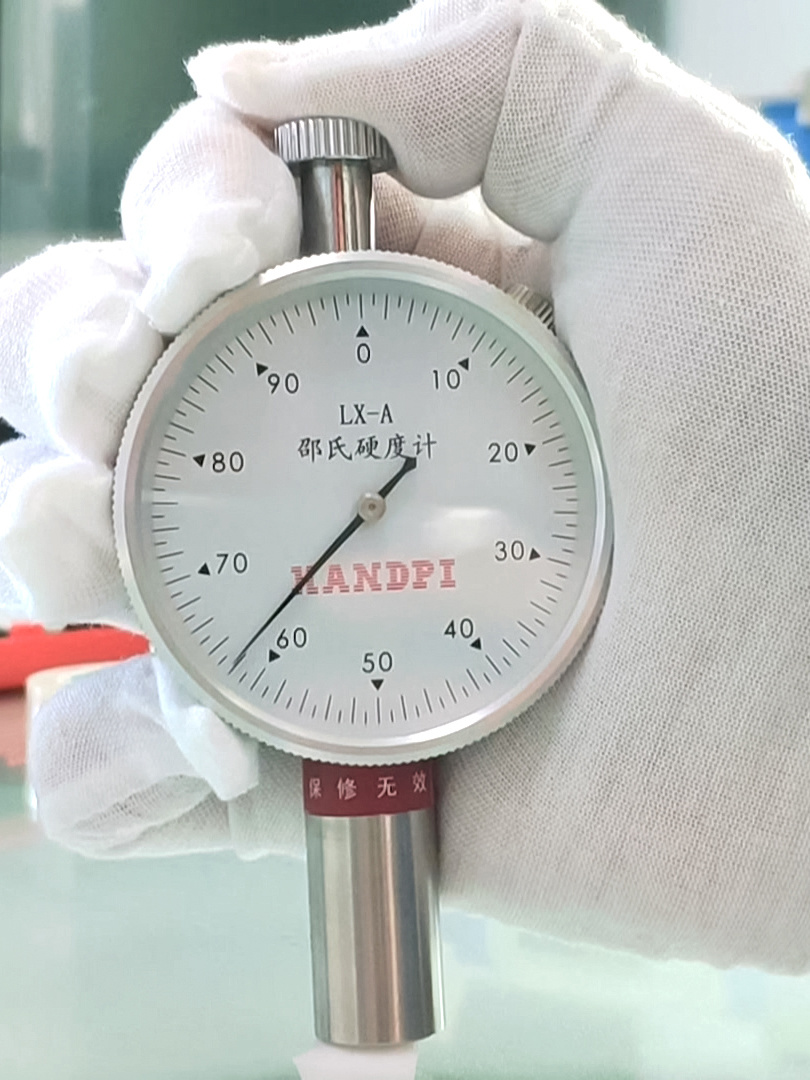

We have a full-time quality control team and an engineering technical team. From mould making, and component production to finished product assembly, we have complete control procedures. Strict control is carried out through 11 quality inspection procedures to ensure the product qualification rate reaches 99%. At the same time, we are equipped with more than 20 sets of quality inspection equipment, such as low-temperature testing equipment, high-temperature testing equipment, tension/compression testing equipment, sharp-point testing equipment, sharp-edged testing equipment, international standard colour-matching light boxes, and simulated vehicle transportation vibration tables.

August • News

Real-time update of plastic toys dynamics